Innovation

PHIL set the industry standard in tailgate design since we introduced the first off-highway Autogate Tailgate to the industry in 1969. Today, we’ve produced more than 10,000 tailgates for both articulated and rigid frame off-highway trucks - from 20 ton to 340 ton in size.

Each fast-opening, fast-acting Autogate Tailgate provides increased payloads, decreased material spillage, improved loading and a balanced load distribution. And, we use a unique, high-strength chain that’s stronger than any commercially available standard chain and oversized gate pivot pins to provide maximum durability.

Whether you’re hauling dirt, sand, gravel, shot rock, coal, oil sands or soupy material, the PHIL Autogate Tailgate keeps material in your truck bed no matter what the condition.

How Does An Autogate Tailgate Increase Your Truck Payload and Productivity?

Without a tailgate, isolated components such as the front suspension, front axle, hoist mechanism, and steering equipment may be overburdened. While attempting to prevent spillage, operators may pile the load forward in the truck bed causing damage to the canopies, overload to the front tires, and side spillage. By closing the rear of the truck, tailgates provide a bigger loading target helping the loader operator distribute the load evenly from the front to the rear of the truck so weight distribution improves.

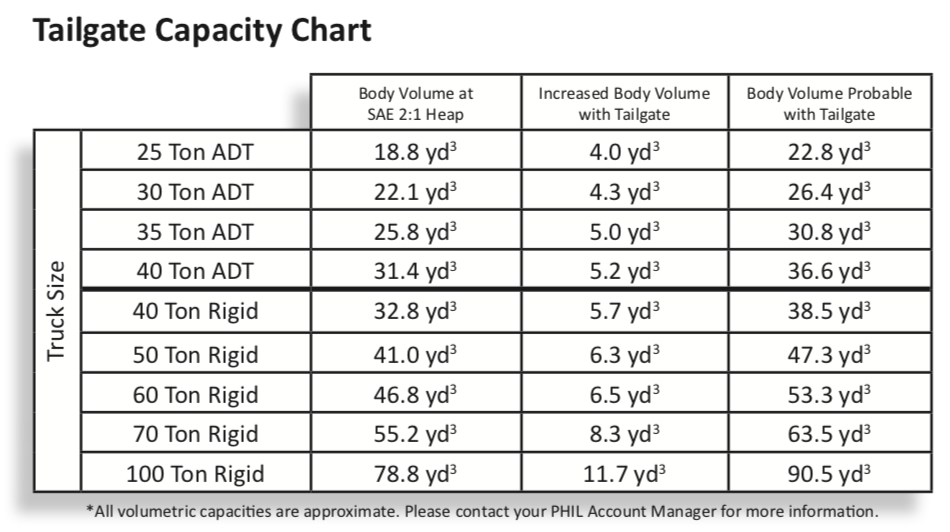

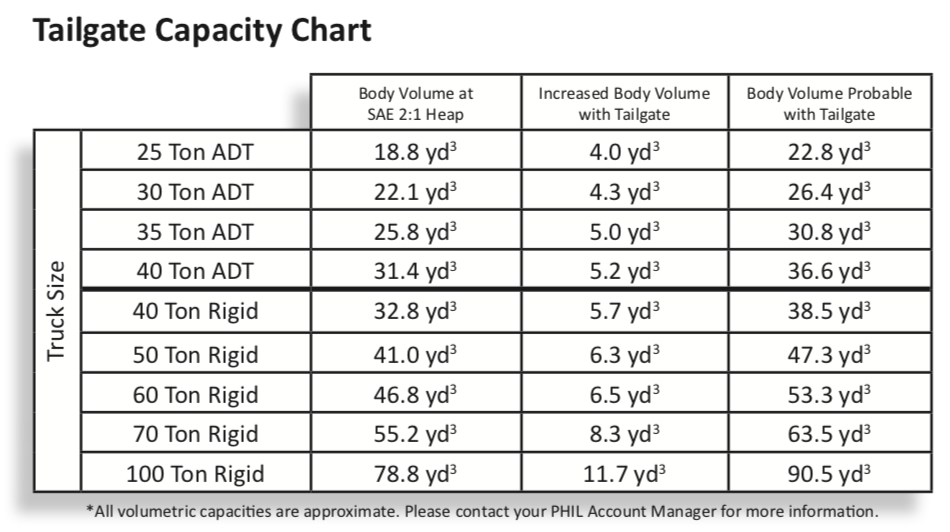

With the truck bed closed, you’ll also realize a volumetric capacity increase of up to 20%, depending on the material hauled.

A direct benefit of tailgates is the elimination of rear-end spillage. When a non-tailgated truck shifts gears on an incline or turns a corner, materials can be lost over the sides or out the rear leading to tire damage. Our Autogate Tailgate reduces side and rear-end spillage by keeping the “rocks-in-the-box”. Drivers steer with ease through clutter-free loading and haulage areas.

Operation of our Autogate Tailgate is simple and trouble-free. No lock, cylinders or controls to malfunction. The body dumps, the Autogate Tailgate opens.

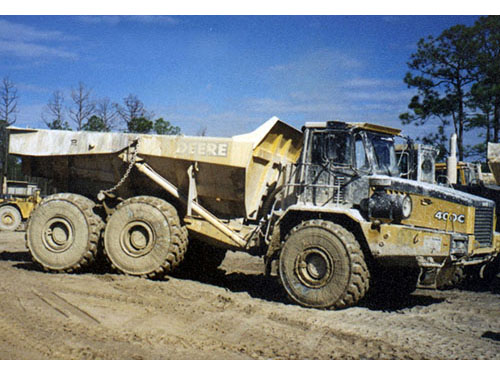

Articulated

Articulated  Construction Duty

Construction Duty Mining Duty

Mining Duty  Komatsu Rigid Frame

Komatsu Rigid Frame  Positive Seal

Positive Seal Ultra-High / Outriggerless

Ultra-High / Outriggerless  In-Service / Out-of-Service

In-Service / Out-of-Service  Sideboards

Sideboards  Load Ejectors

Load Ejectors  Push Blocks

Push Blocks